Overview

- Fact cubage: 18cbm

- Traction type: 6*4

- Steering: Left/right hand drive

- Terms of payment: TT, L/C

- Warranty: One Year

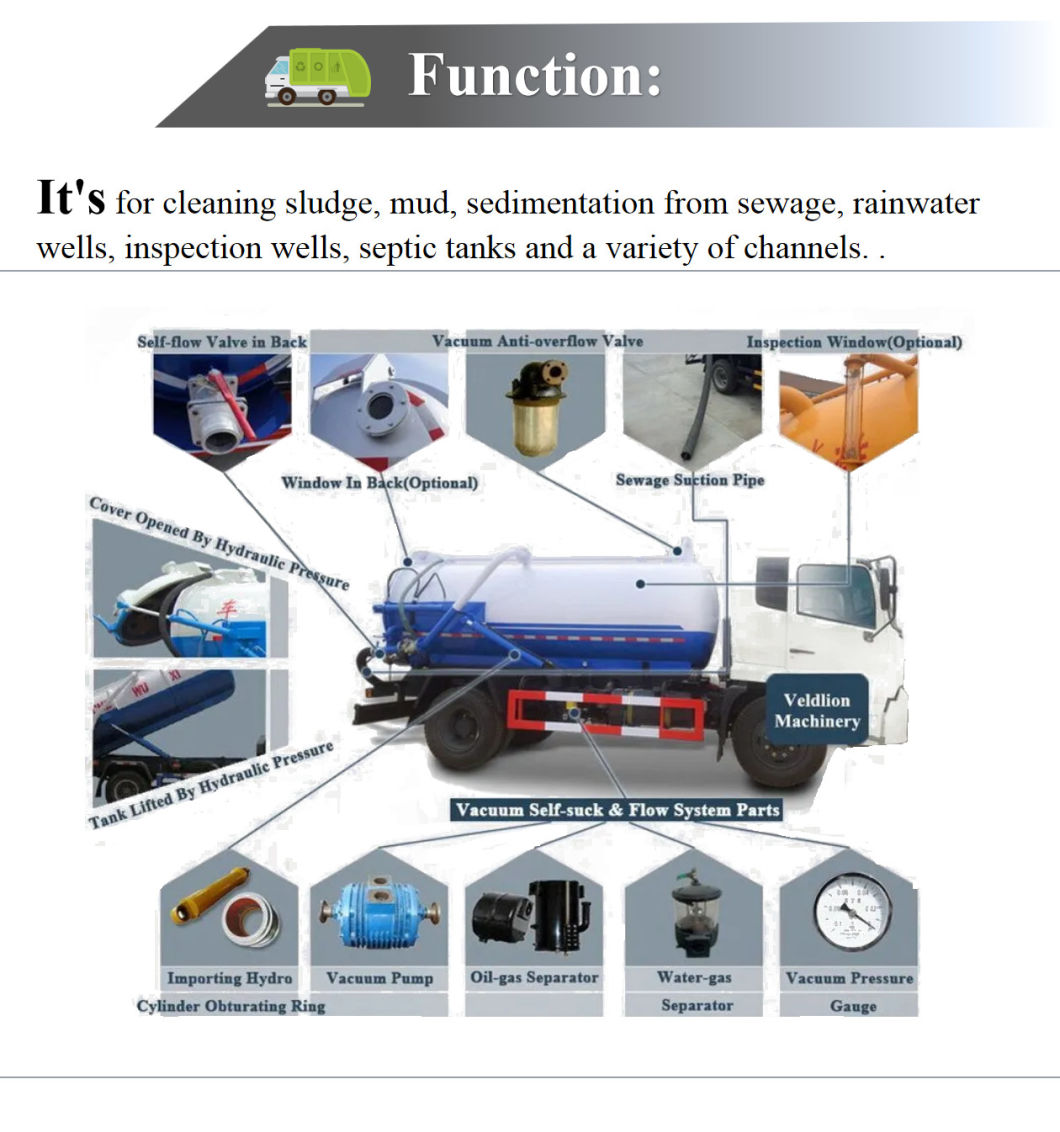

Vacuum sewage suction truck is designed special purposed truck which used to collect, transport and discharge liquid such as dirty water, sludge, septic, crude oil, and solid stuff such as small stones, bricks as well.

Vacuum sewage suction truck's equipped with suction tanker, vacuum pump, hydraulic system and other pneumatic components which could fulfill different requirements of specific operations.

DONGFENG 18cbm Vacuum Sewage Suction Truck Specifications

| Vehicle Description | ||

| Overall dimension | 9600*2500*3300mm | |

| GVW | 25000kg | |

| Curb weight | 10805kg | |

| Chassis brand | DONGFENG KL | |

| Traction type | 6*4, right hand drive | |

| Chassis Description | ||

| Chassis model | DFL1250A8 | |

| Cab | Sleeper cab, forward control type, low roof, new face, all welded steel cab of tilt type, mechanical cab tilting, rear mechanical cab suspension, adjustable driver's seat, air conditioning system, electric windows, central lock. | |

| Wheelbase | 4350+1300mm | |

| Tire specification | 11.00-20 | |

| Tire quantity | 10+1 units | |

| Engine | Engine model | C260 33 |

| Emission level | Euro 2 | |

| Displacement/output | 8300ml/191kw | |

| Horse power | 260hp | |

| Gear box | Type | RT-11509C DD |

| Number of gears | 9 forward gears& 1 reverse, synchronized | |

| Brake system | Full air brake system, split pneumatic circuit; parking spring brake acting on rear axles, exhaust brake | |

| Axle | Front | 7T- Elliot type, I beam section |

| Rear | 10T*2-Single reduction | |

| Suspension | Front | 8- Leaf spring with shock absorber |

| Rear | 9-Leaf spring | |

| Fuel tanker | Type | Steel fuel tank, with lockable cap |

| Capacity | 350L | |

| Up-part description | ||

| Tanker | Capacity | 18cbm |

| Material | Q235B, 6mm thickness | |

| Structure | Welding vacuum tank, cylindrical | |

| Standard configuration | Equipped with hydraulic lifting rear door and lock discharge cover; Equipped with PTO, fecal tank, suction tube and discharging pipe, observing area, clean-out equipment, liquid-alarm device; Equipped with water-cycle pump; Anti-corrosive treatment inside tanker. |

|